New business models like TRUMPF’s “Pay-Per-Part” require the remote operation of machinery without specialist staff on site. Worldwide distributed machines are operated from central remote operation centers. Specialists plan and control the production of those machines. They also fix occurring problems remotely.

One unsolved problem in remote operation is the acknowledgement of machines’ safety systems. Safety regulations restrict remote acknowledgement to non-safety relevant events and are only applicable in the direct surroundings of the equipment. Therefore, safety relevant acknowledgements still require a person on-site.

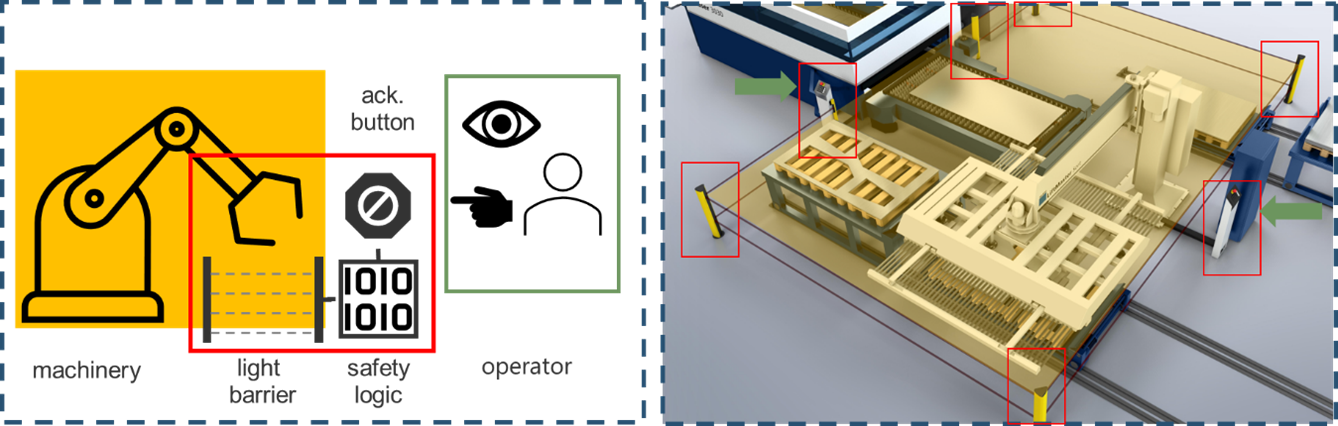

As an example, consider the automatic loading and unloading unit of laser cutting machine (as shown in Figure 1). The unit’s safety area is protected by a multi beam light barrier. The automation component is stopped when the light barrier is interrupted. Before restarting the automation component the operator must make sure that no one is inside the safety area. He acknowledges this at a hard-wired, external control panel close to the safety area.

Figure 1: Hard-wired safety circuit for the on-site acknowledgement; systematic (left) and real world (right) representation.

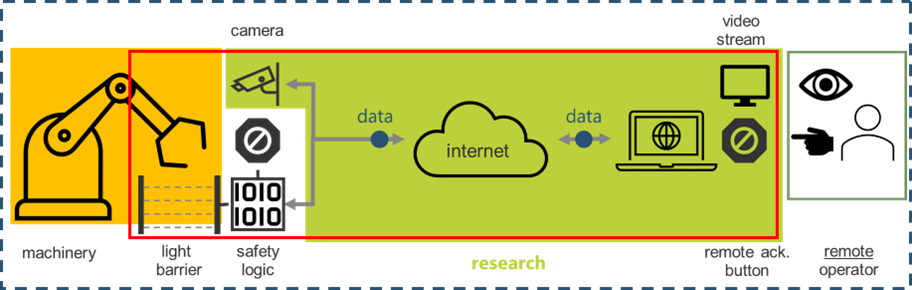

In the project PoQsiKom we are elaborating concepts for acknowledging machines’ safety systems remotely via the internet (Figure 2). Trustworthiness of data and secure communication is essential for realizing this scenario.

Figure 2: Safety circuit closed via the internet with cameras for the remote operator.

For further details please contact us.